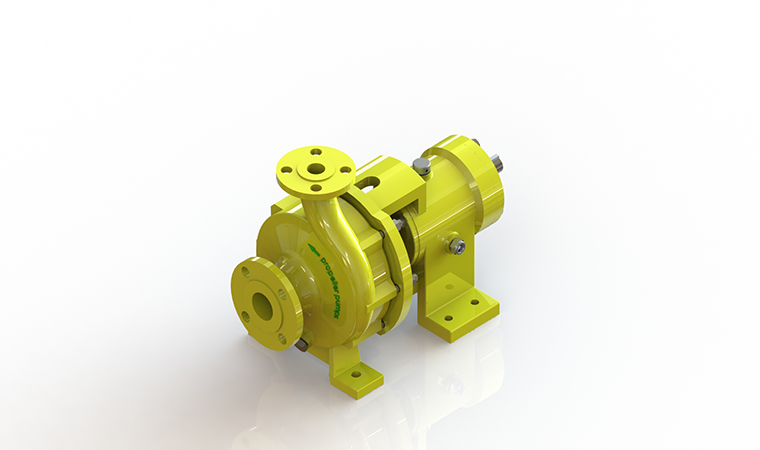

Centrifugal Process Pump

Centrifugal Process Pump

A centrifugal process pump is a type of pump that uses a rotating impeller to create a flow of liquid or gas in a piping system. The impeller is typically a high-speed rotating wheel with vanes that spin and move the fluid outward, creating a centrifugal force that moves the fluid through the pump and into the system.

Centrifugal process pumps are commonly used in the chemical, petrochemical, food and beverage, and water treatment industries, among others. They are designed to handle a wide range of fluids and are ideal for applications that require high flow rates and low to medium pressure.